Blog

The Pirelli Tire Building, designed by noted Modernist architect Marcel Breuer in 1967, is located adjacent to Route 95 in New Haven, CT. Armstrong Rubber Co. originally owned this unique, panel-clad lab and office space from 1970-1988. (

One of the most important drivers in achieving Passive House certification (or achieving any goal!) is getting the project team involved from the start. Becker + Becker, the owner, architect and developer for the creative retrofit of the Pirelli Building, hired SWA’s Passive House, LEED, Enclosures, and Accessibility teams to coordinate during early design. Becker +Becker is invested in rebuilding for resilience, sustainability, and occupant health and comfort and appreciates the necessity of getting goals defined at the outset.

The Pirelli Tire Building, designed by noted Modernist architect Marcel Breuer in 1967, is located adjacent to Route 95 in New Haven, CT. Armstrong Rubber Co. originally owned this unique, panel-clad lab and office space from 1970-1988. (The building was known as The Armstrong Rubber Building.) The building (and Armstrong Rubber) was purchased by the Pirelli Tire Company (1988-2003) and then sold the building to IKEA (2003-2019), although it was left vacant under both ownerships. The building was added to the Connecticut State Register of Historic Places in 2000. Becker + Becker is transforming the office building into a hotel and conference meeting space. Following EnerPHit guidelines and certification, the project plans to run all electric and earn NetZero, LEED Platinum, and ENERGY STAR® certifications.

At construction completion, the planned Phase 1 photovoltaic system–split between the building roof and carport canopies–is expected to produce 558,000 kwh/yr. To reach Net Zero, the building’s onsite energy usage must not exceed the onsite energy production by the PV system. Phase 2 photovoltaic carport canopies that will be completed in the year following construction will cover the remaining energy production and fulfill the project goal of being Net Zero.

One of the biggest challenges in planning for full electrification is the equipment and operation of the commercial kitchen. For the Pirelli renovation project, in addition to electrification of domestic hot water (DHW) and developing a Passive House-level enclosure, limiting kitchen energy use has become a key consideration during the design process.

When picturing your average commercial kitchen, it is likely to imagine fryers, large exhaust hoods and multiple flat-topped grills. The typical commercial kitchen is inherently inefficient with large electrical loads and high exhaust levels. In the design for the Pirelli project, the team decided to take a step back. Instead of “How can we build a standard commercial kitchen and still reach our goals?” the questions were more along the lines of “What improvements to the menu and appliance-use schedule will make this kitchen more efficient?” By asking this question, the team has been able to design with greater efficiency, maintaining staple restaurant menu items (French Fries!), yet still working towards successfully reaching Net Zero and Passive House goals.

The Pirelli Building project is also taking a lead in electrification through the DHW system. In a typical hotel or multifamily building, gas-fired boilers are usually responsible for the large-scale hot water distribution. In this case, an electric heat pump system is specified and will hopefully set the stage for future hotel and multifamily projects in the area.

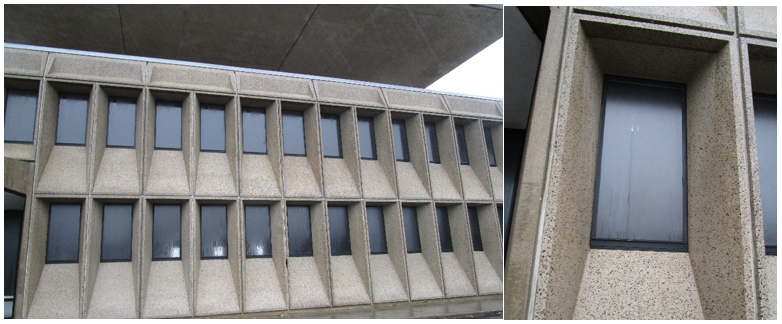

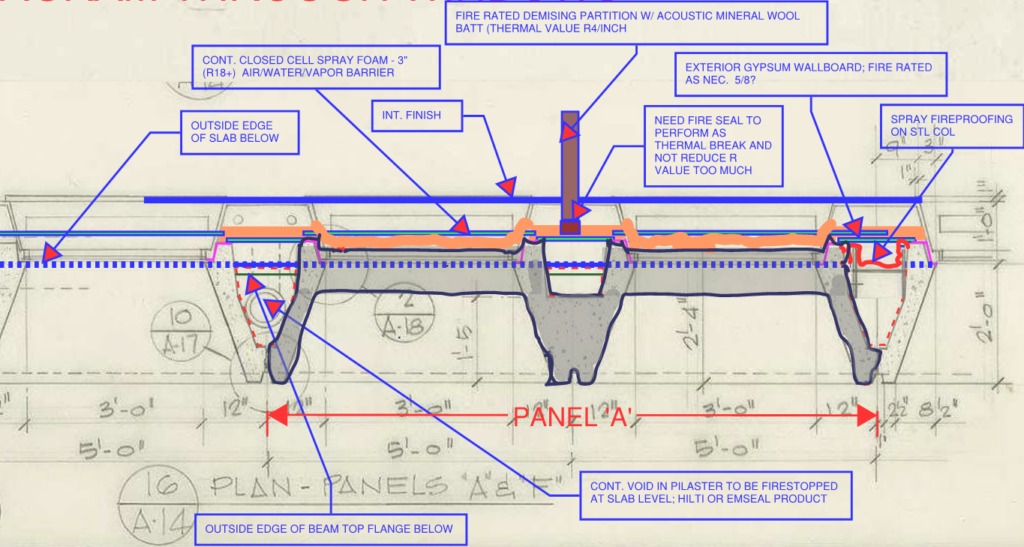

A unique aspect of this project is its status as a Modernist historic landmark. The building presents both challenges and benefits to consider as we take on the task of reducing the carbon footprint of existing buildings, particularly hotels, which we know can be notorious emitters. For the enclosure design, it was essential to keep the exterior façade and the building’s appearance intact (see photos above). Therefore, the insulation, air and vapor barriers for the Passive House-level enclosure will be installed exclusively on the interior of the building. A continuous plane of closed-cell insulation on the interior face of the concrete panels acts as an air barrier and vapor retarder and provides a high R-value for the walls and roof. The SWA Enclosures team provided detailing of the continuous thermal breaks (aerogel-containing spray, tape, and insulating blocks) and condensation control for tight spaces around window and door openings in order to maintain the historic fabric while achieving Passive House and LEED goals (see detail below). Selecting triple pane windows that most resembled the existing historic windows will aid in airtightness and overall efficiency of the building.

In addition to the aggressive energy goals of this project, the preservation of the building’s concrete shell and mixed concrete and steel structure creates a much lower embodied carbon impact than if the building had been demolished, contributing to an increasingly important conversation about carbon emissions associated with building and materials.

SWA is proud to take part in the efforts to preserve this historic building and to create a healthy and comfortable environment for future occupants. As our team continues to consult on the project, we will be sharing the project achievements, so be on the lookout for a follow up on the embodied carbon and other LEED highlights.

Join us for a virtual tour and presentation of the Pirelli retrofit:

Contributors: Kate Doherty, Building Systems Analyst; Dylan Martello, Senior Building Systems Consultant

Steven Winter Associates